Peroxibenzoato de terc-butilo (TBPB) CAS 614-45-9: aplicaciones, seguridad e información clave

Fecha de lanzamiento: 19/11/2024

Peroxibenzoato de terc-butilo El TBPB, cuya fórmula química es C10H12O2 y cuyo número CAS es 614-45-9, es un compuesto químico muy versátil que se utiliza ampliamente como iniciador de radicales en procesos de polimerización. Es un ingrediente fundamental en la producción de polímeros, termoplásticos, resinas y diversos materiales industriales de alta calidad. En este artículo, analizaremos en profundidad los usos, las propiedades, las precauciones de seguridad y las consideraciones clave para la compra de TBPB, lo que le proporcionará una descripción general completa de su importancia en la industria química.

¿Qué es el peroxibenzoato de terc-butilo (TBPB)?

El peroxibenzoato de terc-butilo, comúnmente conocido como TBPB (CAS 614-45-9), es un compuesto de peróxido orgánico que desempeña un papel crucial en el inicio de las reacciones de polimerización. El TBPB se utiliza principalmente en la industria química para iniciar la polimerización de monómeros, como el estireno y los acrílicos, para crear polímeros y resinas duraderos. La estructura del TBPB incluye un grupo peroxi (-OO-) unido a un anillo de benceno, lo que le da su reactividad única en los procesos químicos.

Propiedades químicas del TBPB:

- Fórmula molecular: C10H12O2

- Número CAS: 614-45-9

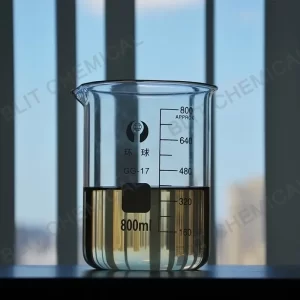

- Aspecto: Sólido de color blanco a amarillo claro.

- Temperatura de descomposición: 60-80°C

- Pureza: Disponible en varios grados según el uso industrial.

Aplicaciones del TBPB en procesos industriales

- Iniciador de polimerización

La principal aplicación del peroxibenzoato de terc-butilo (TBPB) es como iniciador de polimerización. Cuando se calienta, el TBPB se descompone para producir radicales libres que inician la polimerización de monómeros, creando polímeros y termoplásticos de alta calidad. Este proceso es esencial en la fabricación de plásticos para industrias como la automotriz, la de empaquetado y la electrónica. La eficacia del TBPB en las reacciones de polimerización lo convierte en una opción ideal para producir polímeros de alto rendimiento con estabilidad térmica y resistencia mecánica superiores.

2. Agente reticulante en resinas

El TBPB también se utiliza ampliamente como agente de reticulación en la producción de resinas. La reticulación mejora las propiedades físicas del polímero, incluidas su resistencia térmica, resistencia química y resistencia mecánica. Esto es particularmente importante en la producción de recubrimientos industriales, adhesivos y compuestos, donde se requiere una mayor durabilidad del material.

3. Producción de productos químicos especializados

Además de la polimerización y la reticulación, el TBPB también se utiliza en la síntesis de productos químicos especiales, como agentes de curado y estabilizadores. Su capacidad para generar radicales libres de manera eficiente permite su uso en una variedad de procesos de síntesis química, especialmente cuando se necesitan reacciones controladas impulsadas por radicales.

Cómo funciona el TBPB en las reacciones de polimerización

El proceso de polimerización que implica TBPB comienza con la descomposición térmica del compuesto. A temperaturas elevadas (60-80 °C), el TBPB se descompone en dos radicales libres. Estos radicales son altamente reactivos e inician la polimerización de monómeros como el estireno o el ácido acrílico, convirtiéndolos en polímeros de cadena larga. Este proceso es fundamental para producir termoplásticos, elastómeros y resinas que se utilizan en una amplia gama de aplicaciones.

Seguridad y manipulación de TBPB

Al igual que con cualquier peróxido orgánico, es esencial manipularlo adecuadamente y tomar medidas de seguridad al trabajar con peroxibenzoato de terc-butilo. Debido a su naturaleza reactiva, el TBPB puede presentar riesgos si no se maneja correctamente. A continuación, se ofrecen algunos consejos de seguridad para trabajar con TBPB:

Precauciones de seguridad

- Equipo de protección:Utilice siempre guantes, gafas y ropa protectora al manipular TBPB para evitar el contacto directo con la piel o los ojos.

- Almacenamiento adecuado: Guarde el TBPB en un lugar fresco y seco, alejado de la luz solar directa, el calor y productos químicos incompatibles como ácidos o bases. La temperatura ideal de almacenamiento es inferior a 25 °C.

- Ventilación: Utilice TBPB en áreas bien ventiladas para evitar la inhalación de humos o vapores nocivos producidos durante la descomposición o manipulación.

Consideraciones sobre la eliminación

Al desechar TBPB, respete siempre las normas ambientales locales. Está clasificado como una sustancia peligrosa y no debe desecharse en los sistemas de agua ni en los desagües habituales. Trabaje con un servicio de eliminación certificado para garantizar una manipulación y eliminación seguras.

Cumplimiento normativo para TBPB

El peroxibenzoato de terc-butilo está sujeto a diversos requisitos reglamentarios, entre ellos:

- REACH (Registro, evaluación, autorización y restricción de sustancias y preparados químicos) Regulaciones en la UE

- OSHA (Administración de Seguridad y Salud Ocupacional) Normas en los EE.UU.

- Directrices de la EPA Para uso y eliminación seguros

Es esencial que los fabricantes y proveedores cumplan con estas regulaciones para garantizar el uso seguro de TBPB en los procesos industriales.

Cómo comprar TBPB (CAS 614-45-9)

Al comprar peroxibenzoato de terc-butilo (TBPB), es importante elegir un proveedor confiable para asegurarse de recibir un producto que cumpla con los estándares de la industria. A continuación, se ofrecen algunos consejos para comprar TBPB:

- Comprobar pureza: Asegúrese de que el TBPB cumpla con los niveles de pureza necesarios para su aplicación específica. El TBPB de alta pureza es esencial para una polimerización uniforme y eficiente.

- Opciones de embalaje: TBPB está disponible en varias opciones de embalaje, desde pequeños contenedores para uso en laboratorio hasta grandes cantidades para producción a gran escala. Elija el tamaño adecuado según sus necesidades.

- Reputación del proveedor: Trabaje con proveedores establecidos que sean conocidos por su confiabilidad, cumplimiento de normas de seguridad y productos de calidad. Las opiniones y certificaciones de los clientes pueden ayudarlo a elegir un proveedor confiable.

Los mejores proveedores de peroxibenzoato de terc-butilo

Si quieres conseguir Peroxibenzoato de terc-butilo de alta calidad, pero no sabes cómo elegir, también puedes intentarlo lío. Como profesional Proveedor de peroxibenzoato de terc-butilo, lío Podemos ofrecerle productos y servicios de alta calidad. ¡Le invitamos a ponerse en contacto con nosotros para obtener información detallada sobre pedidos y servicios!

Conclusión: ¿Por qué el TBPB es esencial en la química de polímeros?

El peroxibenzoato de terc-butilo (TBPB) (CAS 614-45-9) es una sustancia química vital en la química de polímeros, con aplicaciones que van desde iniciadores de polimerización hasta agentes de reticulación. Su capacidad para generar radicales libres lo hace indispensable para la producción de polímeros, resinas y termoplásticos de alta calidad en industrias como la automotriz, los recubrimientos y el embalaje.

Si sigue las pautas de seguridad adecuadas y compra a proveedores confiables, podrá asegurarse de que TBPB se utilice de manera eficiente y segura en sus procesos de producción.